+ 10 Series Coating Laminating

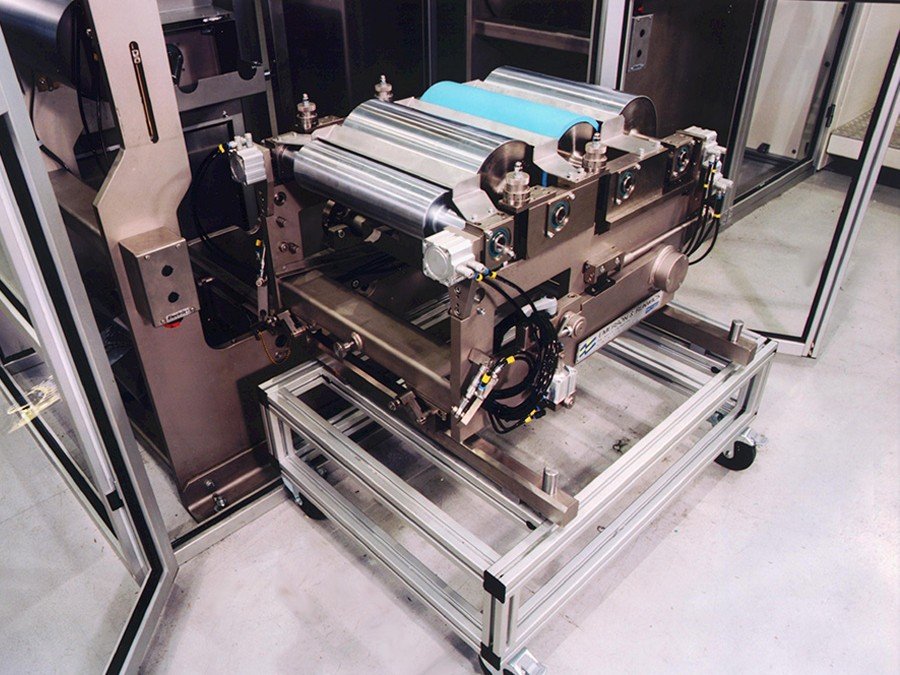

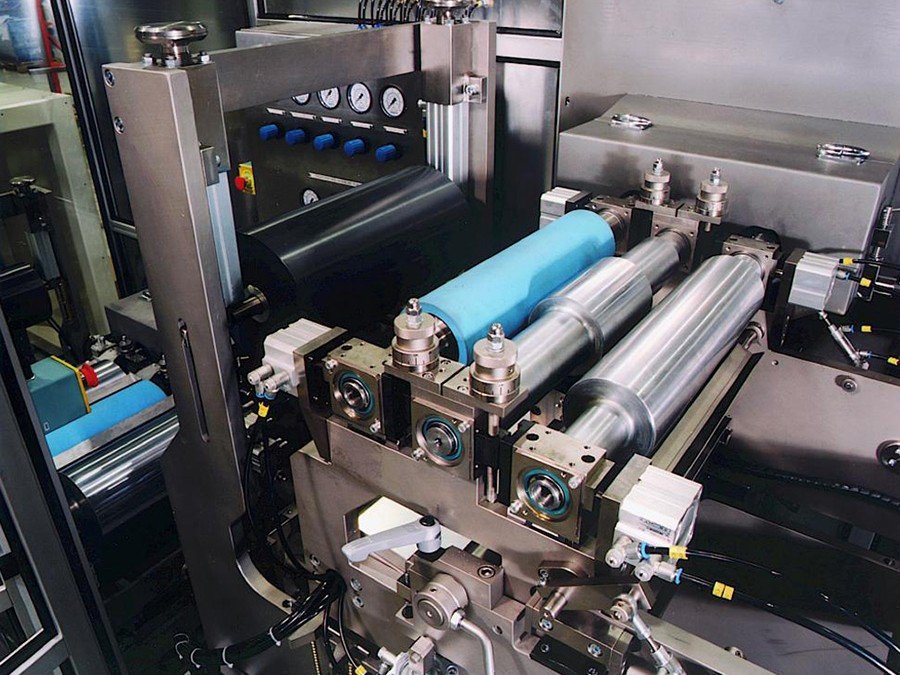

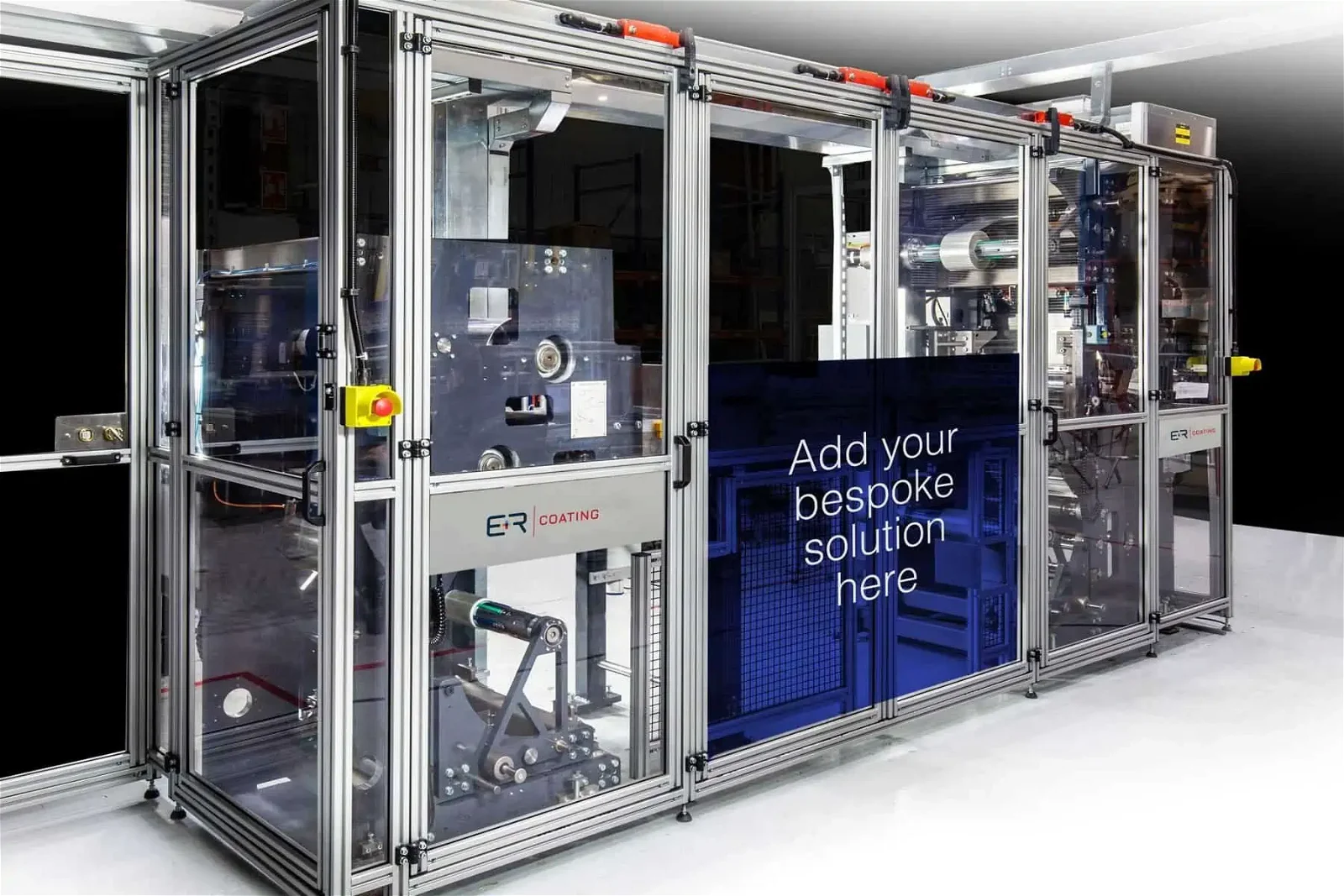

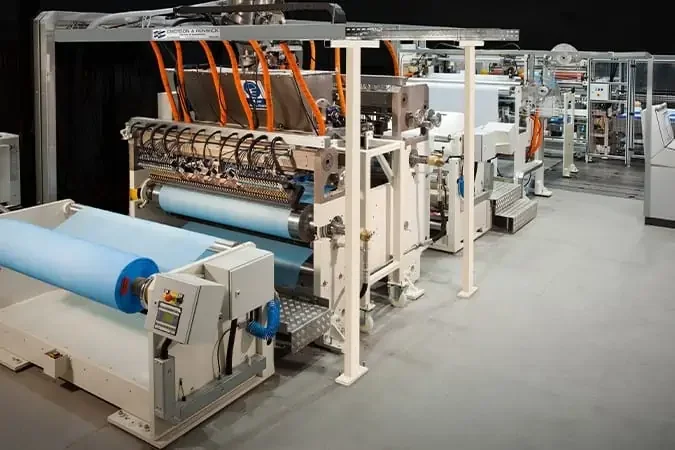

E+R’s highly configurable Series production platforms will enable your roll-to-roll product development utilising the latest web transport and drying principles and coating techniques for the most sensitive and demanding substrates.

With custom-designed solutions to meet exact and repeatable process conditions, we apply creative problem solving to our customers’ challenges - maximising productivity and ROI.

Best 10 Series Coating Laminating

Key Features:

- Widths Min 300mm -1200mm

- Configurable for two side coating

- Unwind/Rewind Units

Various solutions including Automatic Splicing for continuity of operation:

- Slot-die – Single/Double side/Patch/Stripe options

- Gravure Coating & Printing: Offset, Kiss each with forward &

- Reverse direction application

- Flexographic Printing & Patterning

- Multi-roll coating: 5 & 6 Roll

- 2 & 3-Roll Reverse

- 3 Roll Forward

- Air Knife

- Knife Over Roll

- Meyer Bar

- Wet and Dry Lamination, Cooling, Web cleaning, Corona Treatment, Conditioning

Hot Air Impingement Dryer Applications:

- Air Flotation, Roller Support

- Independent temperature and air velocity control

- Variable velocity nozzles

- Laminar airflow capabilities for challenging coatings

- IR variants

- Atmospheric and inert gas UV

- Heating by Gas, Electric or Thermal Oil

- Air Impingement Cooling

- Clean room capability as required.

- Turnkey Installations

- Maintenance contracts

- Remote diagnostics

+ Custom development for all production coating and laminating equipment

Our objective is to provide you with the ultimate solution that completely matches your needs, so our engineers will work with you from the concept stage to ensure you have the best possible design.

We develop and manufacture world-class pilot + production coating and laminating equipment.

+ Engineering Capabilities

Experienced mechanical and electrical assembly and installation engineers

- Wide experience across diverse range of applications

- Mechanical assembly, set-up and calibration of machine sections in-house

- In-house panel build for control cubicles

- Installations completed globally, turn-key start-ups possible

Machine shop for the manufacture of key components

- Equipment portfolio focussed on key elements of machinery – machine frames and ties, rollers, precision components

- Early/late shift pattern

- Complete ‘ownership’ of critical components

Tool room for manufacture of precision components

- Precision equipment – wire EDM, CNC grinding and finishing

- Precision inspection and component validation equipment – CMM, Jodon etc.

Certified to ISO 9001: 2015 quality system

- Component inspection and quality validation

- Assembly validation and sign-off at FAT and SAT

- View our Quality Policy Click here

+ Manufacturing Capabilities

Experienced mechanical and electrical/control engineering team

- 18 full-time engineers

- Web transport, roller design, web guiding, spreading etc.

- Drying technologies

- Coating technologies

- Machinery sub-systems – pneumatics, hydraulics, cooling systems, vacuum

Mechanical design in 3D drafting system with sophisticated FEA

- Complex stress analysis of vacuum vessels ensures optimal design

- Stress deflection analysis for optimal precision and accuracy

Full control systems design – hardware and software

- Electrical control cubicles, HMI and operator pendants

- Wide variety of vendors – Rockwell, Siemens, Bosch Rexroth, Mitsubishi etc.

- Fully compliant safety systems

- Software design and implementation

- Complex drive algorithms – registration, dynamic positioning, tension sensitivity and processing

- Testing and commissioning of systems by E+R staff

+ Advanced Coating Solutions

+ Genesis Air – Lab Series R&D

Highly configurable Lab Series Platform enabling your roll-to-roll product development.

+ 1 Series Development Pilot Scale

Enables roll-to-roll product development from proof of principle to full-scale production.

+ 10 Series Coating Laminating

Utilising the latest coating techniques for the most sensitive and demanding substrates.

+ 20 Series Coating Laminating

Custom-designed solutions and creative problem solving for our customers’ challenges.

+ Series Winders

Leading edge technology Series Winder platform created from a wealth of innovation and experience.

+ Have you got a question for our Coating Team?

Please fill in your details below and a member of our dedicated team will be in touch. Please complete as much information as you so that we can make sure the right person picks up your enquiry.

+ Coating Technical Articles

Our team has a wealth of knowledge and expertise built up over decades of experience in their fields of specialism. Read our technical articles to find out how we have used this expertise, with creative problem solving and critical thinking, to meet and surpass our customers’ needs.

Nothing found.