E+R are world-leading providers of the best print machinery and coating machines for the printing, wallpaper, and wallcovering industries.

Founded in 1918 in Lancashire, the traditional home of the wallcovering industry, over the years E+R has played a vital role in the design and development of special printing machinery, wall covering, and wallpaper manufacturing machinery. E+R enjoys a close relationship with leading manufacturers in the UK and right across the world.

E+R’s print division encompasses both wallcovering and wallpaper equipment as well as a wide range of printing and web converting industries.

We don’t just produce new, bespoke equipment we also refit, redrive and refurbish print stations from other manufacturers to help you become as competitive as possible.

Our relentless investment in research and development programmes ensure that E+R’s machines are designed and built to incorporate state-of-the-art features.

We don’t produce generic machines for the wallpaper and wall covering industry we take the time to understand exactly what your needs are, not just producing the worlds finest machinery but working in partnership with you to reduce costs and improving your competitiveness in the world market.

+ Experience

E+R is a world-leading equipment engineering company. We have grown and developed across a number of market sectors including Print, Forming, Vacuum and Coating and we are proud to be a leading manufacturer of sophisticated roll-to-roll production machinery.

+ Expertise

E+R puts innovation, creativity and invention at the heart of everything we do. We continue to invest in research projects to explore the limits of engineered solutions for our customers and we are committed to challenging the status quo.

We work collaboratively with partners in private industry and from the world of academia to ensure we remain at the cutting edge of innovation.

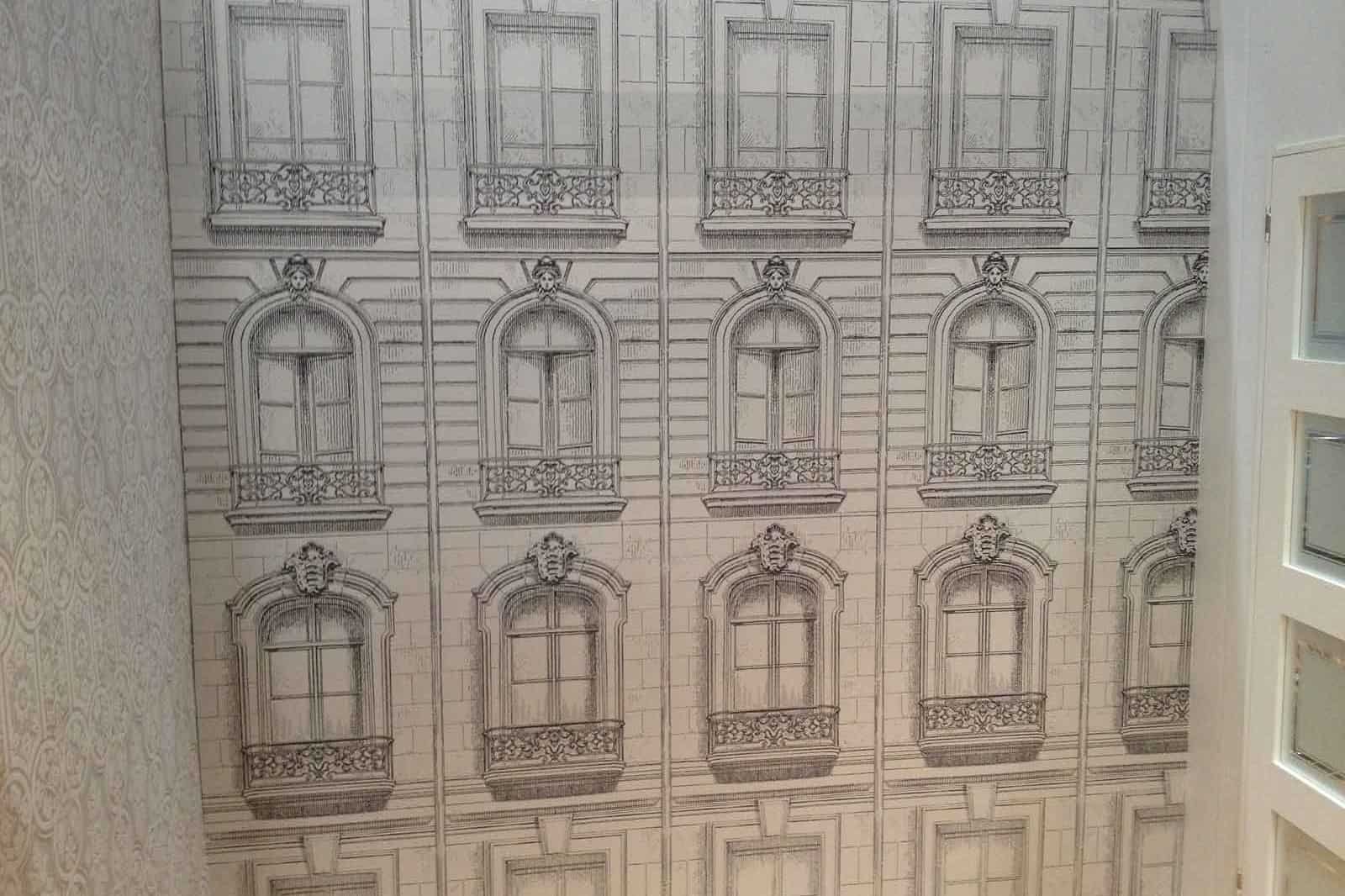

+ Advanced coating, printing and embossing machines for the printing, wallpaper and wallcovering market

+ Commercial Wallcovering Lines

High-speed printing, laminating and embossing machinery with special features for commercial needs.

+ Coating Machines

The full range of coating machines ideal for wallpaper and wallcovering production.

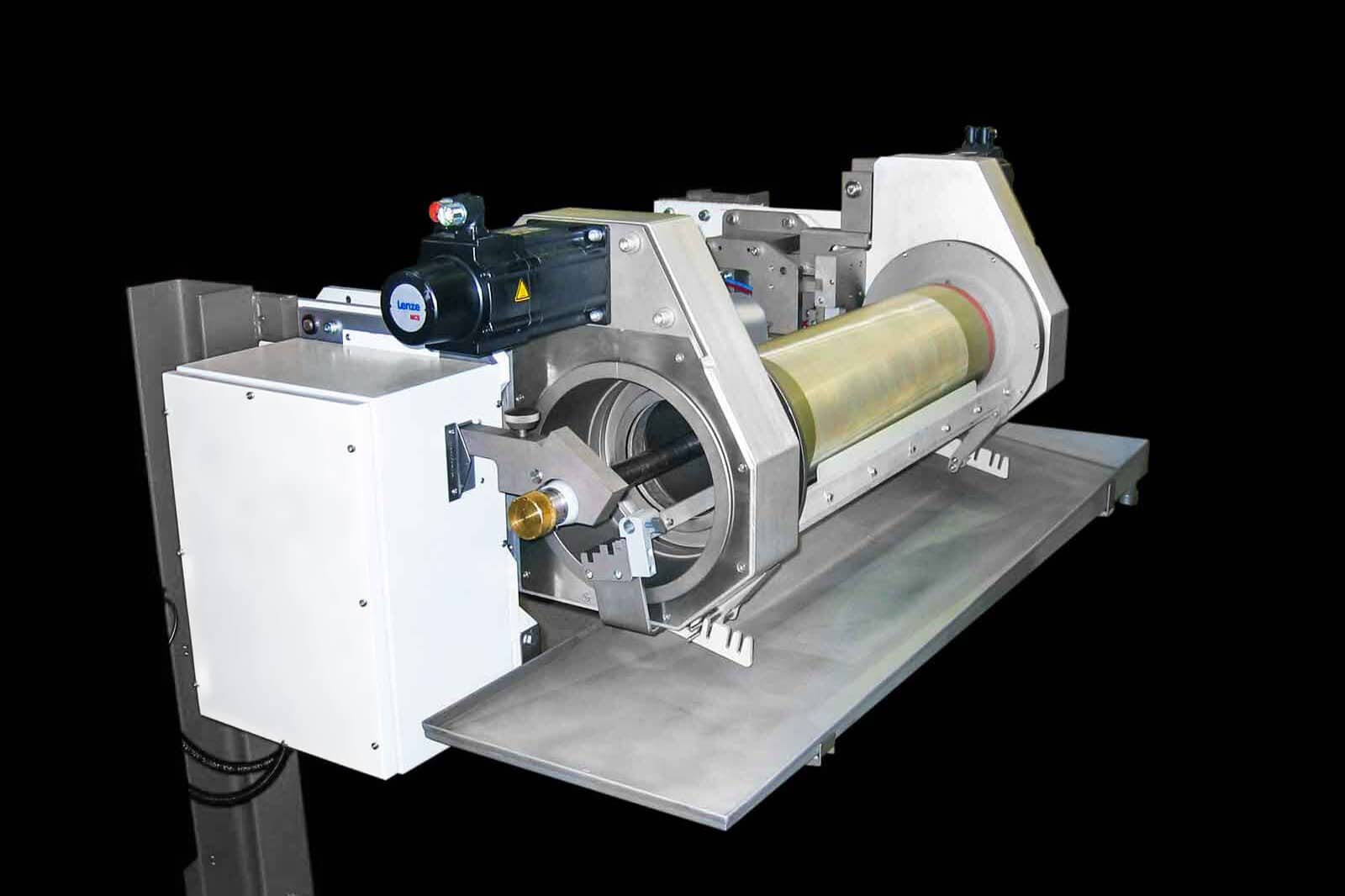

+ Gravure Printer

Special features make colour change quicker and improve press utilisation.

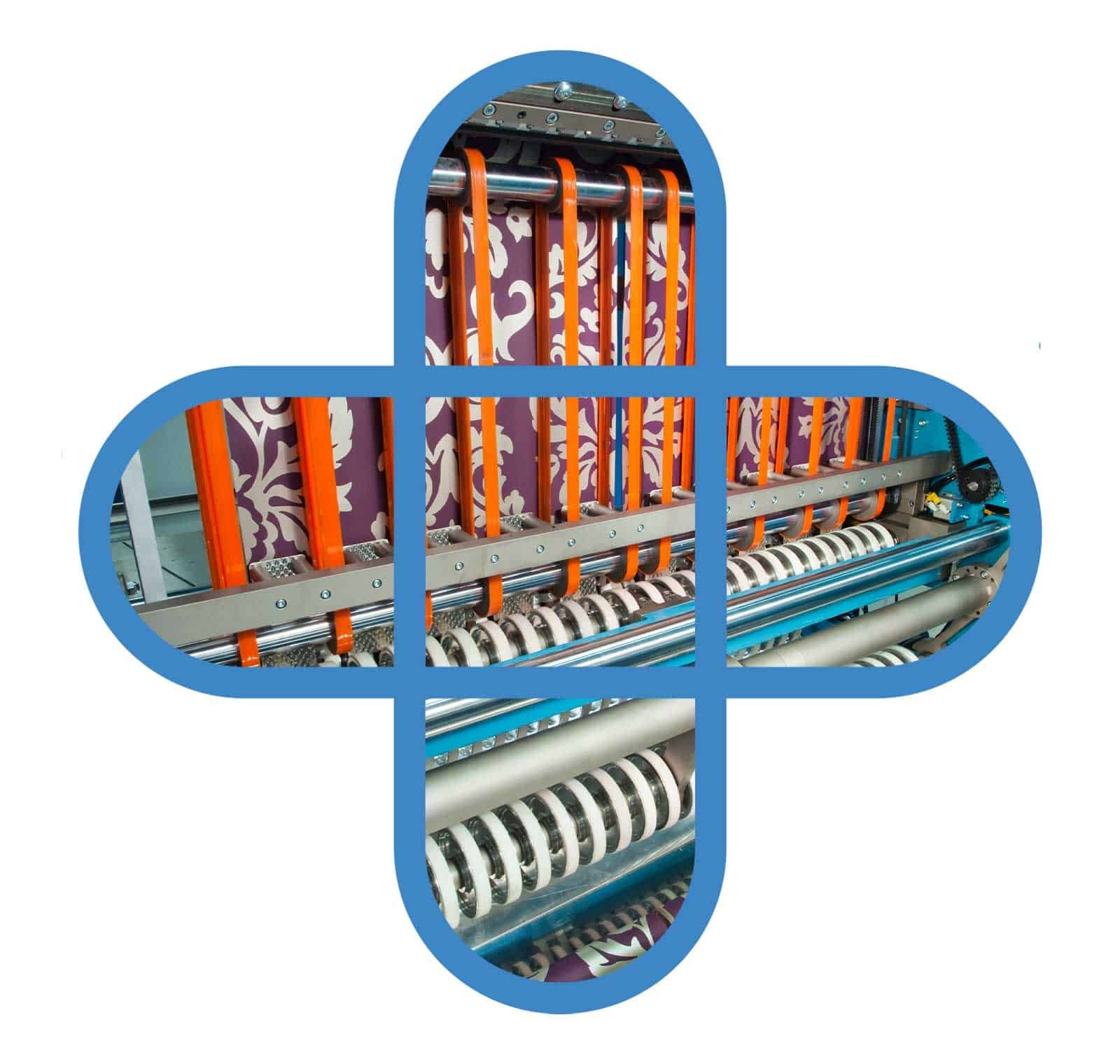

+ Flexo Printing

Custom manufacturing of flexo printing equipment from the development of full flexo printing lines to the creation of integrated flexo printing modules onto your existing workflow.

+ Embossing Machinery

World-renowned embossers used by leading European wallpaper manufacturers.

+ Piece Winders

Whether its rewinding a web into a large diameter reel for further processing or winding finished rolls of wallpaper ready for wrapping we have range of options for you at various widths.

+ Retrofit and re-drives

We're Specialists in the retrofitting and redriving of existing machines - whatever the manufacturer

+ Coating, Embossing equipment, Printing Machine manufactured to your specification

E+R demonstrates an in-depth understanding of our clients’ printing needs in an ever-changing market. we develop Advanced printing and coating machines for worldwide application in the printing, wallpaper and wallcovering marketplace.

Our experienced and dedicated team include designers, engineers, creative problem-solvers and critical thinkers who are committed to creating the best possible solution for your project or challenge.

Creating new technology and applying this to the machinery we produce is our key focus.

+ Whatever the future hold for the printing, wallpaper printing machinery and wallcovering marketplace, E+R will be leading the way

E+R leads the way in developing new products for the changing needs of the wallcovering industry.

We offer the most comprehensive range of print machinery for sale to all types of wallpaper and processes including gravure printing presses, rotary screen printing presses, combination presses for screen and gravure printing, combination presses for embossing and flexo-gravure printing and in-register hot embossing for PVC-based materials.

- Web widths to suit requirements up to 1680mm

- High speed in register Duplex & Flexo printing machines

- In line coating machines for applying plastisols, pre-pastes, ground coats and washable lacquers using several methods of application. (screen, reverse & knife over roll)

We can also offer full advice for all aspects of wallcovering manufacturing including a complete turnkey solution which includes factory layout, services, material flow, product handling Installation, commissioning and operator training, and material supplier introductions.

+ After sales and support

We are committed to providing the highest levels of customer service throughout your journey of working with E+R.

We have services centres based in the UK, Asia and the United States to provide prompt Service Support, Condition Monitoring, Service Plans, Spares and Technical Consultancy.

Our After Sales team will support you with any additional requirements and are on hand to offer advice at any stage of your product or project’s development.

E+R offer a range of planned maintenance contracts for Print and appraisal services for those looking to review machine condition or plan refurbishment or upgrades.

Advanced development for printing, wallpaper and wallcovering machinery

+ Engineering Capabilities

Experienced mechanical and electrical assembly and installation engineers

- Wide experience across a diverse range of applications

- Mechanical assembly, set-up and calibration of machine sections in-house

- In-house panel build for control cubicles

- Installations completed globally, turn-key start-ups possible

- Factory layout, service’s, material flow, product handling Installation, commissioning and Operator training & Material Supplier introductions.

Machine shop for the manufacture of key components

- Equipment portfolio focussed on key elements of machinery – machine frames and ties, rollers, precision components

- Early/late shift pattern

- Complete ‘ownership’ of critical components

Toolroom for manufacture of precision components

- Precision equipment – wire EDM, CNC grinding and finishing

- Precision inspection and component validation equipment – CMM, Jodon etc.

Certified to ISO 9001: 2015 quality system

- Component inspection and quality validation

- Assembly validation and sign-off at FAT and SAT

- View our Quality Policy Click here

+ Manufacturing Capabilities

Experienced mechanical and electrical/control engineering team

- 18 full-time engineers

- Web transport, roller design, web guiding, spreading etc.

- Drying technologies

- Coating technologies

- Machinery sub-systems – pneumatics, hydraulics, cooling systems, vacuum

Mechanical design in 3D drafting system with sophisticated FEA

- Complex stress analysis of vacuum vessels ensures optimal design

- Stress deflection analysis for optimal precision and accuracy

Full control systems design – hardware and software

- Electrical control cubicles, HMI and operator pendants

- Wide variety of vendors – Rockwell, Siemens, Bosch Rexroth, Mitsubishi etc.

- Fully compliant safety systems

- Software design and implementation

- Complex drive algorithms – registration, dynamic positioning, tension sensitivity and processing

- Testing and commissioning of systems by E+R staff

+ Case Studies

Discover more examples of production machinery and engineering projects for the printing, wallpaper and wallcovering market place. Our unique combination of design expertise, advanced engineering skills and expert customer service sets the standard worldwide. Projects where innovation, simplicity of design and inbuilt reliability come as standard.

+ Slip-printing system for rotary screen allows new creative opportunities

Whilst many of our competitors choose to depend on gears all E+R screen heads have direct-driven AC servo motors directly driving each screen head for increased precision and control with non of the back-lash or wear associated with geared systems..

+ E+R pioneer fast-swap screen size for screen print industry

E+R's unique fast-change system for print repeat sizes allows a 5-minute change time. The innovative yet simple solution significantly reduces cost, downtime and heavy lifting.

+ E+R patent ‘Mega-repeat’ system for sophisticated skip printing

E+Rs expertise in Screen Heads and Registration System we were able to combine these technologies with sophisticated electronic controls to give a feature that enables an image to be printed on a repeat different to that of the rotary screen.

+ Have you got a question for our Print, wallcovering and coatings Team?

Please fill in your details below and a member of our dedicated team will be in touch. Please complete as much information as you so that we can make sure the right person picks up your enquiry.