We’re world-leading providers of low carbon coating and vacuum machines for making numerous eco-friendly products

Throughout our history, spanning more than a century, we’ve acquired a justified reputation for innovation in engineering, technology, and process.

Our inventiveness has allowed numerous customers throughout the world to enhance their capabilities and productivity greatly, across a wide range of applications.

We’ve also demonstrated an unsurpassed ability to adapt the know-how we’ve acquired over the years to meet the needs of current manufacturers.

Nobody familiar with our heritage is therefore surprised that we’re now in the vanguard of industry’s worldwide war against carbon emissions.

For example, we’re one of seven world-class UK-based organisations who’ve agreed to combine in a ground-breaking project under the auspices of the globally renowned Faraday Institution which aims to develop leading-edge prototype solid-state battery technology for automotive applications. Solid-state batteries contrast with lithium-ion and other types, which contain liquid or polymer gel electrolytes, and could transform the UK’s quest to reach net-zero carbon emissions by 2050, through electrifying transport and devices.

We also signed the Pledge to Net Zero and therefore committed to taking a leadership role in delivering UK greenhouse gas emissions in line with a temperature rise of well below two degrees Celsius. We did this well before we again emphasised our commitment by attending COP 26, the United Nations climate change conference in Glasgow during November 2021.

On a day-to-day basis, we’ve launched a three-pronged attack, reducing our own carbon footprint plus enabling customers to cut theirs and make environmentally friendly products, through our business units.

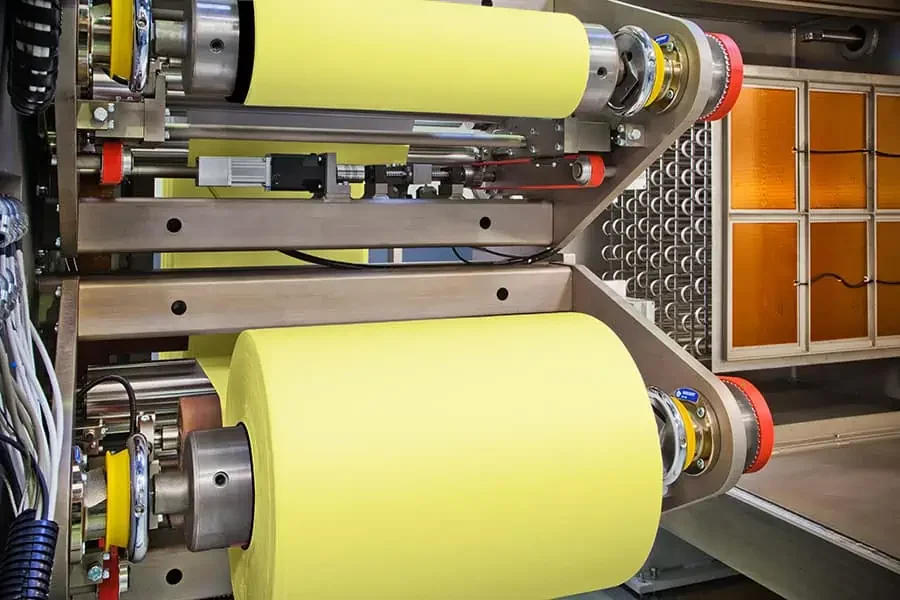

For at least a decade, we’ve been developing low carbon roll-to-roll solutions for a wide range of manufacturing processes. These machines incorporate robust design, operate with numerous substrates, provide expansive web widths and offer scalability. This development has been aided by the scientists in our in-house technology centre, who assist our customers and ourselves, and often work on game-changing projects with outside companies or universities.

Turning to the future, our Process and Equipment Development Director Nick Butcher says:

“By our continued business evolution and investment in innovation, we’ll carry on sharing our passion and ideas for how we’ll drive this new era for the E+R Group. Our teams will continue to focus on providing modern, economical and environmentally considered manufacturing machinery for low carbon-promoting industries.”

On this page, you can discover more about some of our current low-carbon products. We call these offerings our Horizons range.

+ Experience

E+R is a world-leading equipment engineering company. We have grown and developed across a number of market sectors including Print, Forming, Vacuum and Coating and we are proud to be a leading manufacturer of sophisticated roll-to-roll production machinery

+ Expertise

E+R puts innovation, creativity and invention at the heart of everything we do. We continue to invest in research projects to explore the limits of engineered solutions for our customers and we are committed to challenging the status quo.

We work collaboratively with partners in private industry and from the world of academia to ensure we remain at the cutting edge of innovation.

+ Advanced solutions for producing green goods, such as batteries, fuel cells and solar.

+ Coating

We’re major providers of laboratory to production scale coating machinery for energy storage device makers. This equipment helps to produce products such as solid-state batteries and fuel cells.

Solid state batteries contrast with lithium-ion and other types, which contain liquid or polymer gel electrolytes, and are instrumental in the quest to reduce carbon emissions. Fuel cells convert the chemical energy of elements such as hydrogen and oxidising agents like oxygen into electricity.

We also provide development solutions through our in-house technology centre and team of expert, highly qualified scientists.

Our Horizons range of coating machinery for energy storage device production includes the Genesis Air plus Series 1 and 10 coaters.

+ Genesis Air – Lab Series R&D

Highly configurable Lab Series Platform enabling your roll-to-roll product development.

+ 1 Series Development Pilot Scale

Enables roll-to-roll product development from proof of principle to full-scale production.

+ 10 Series Coating Laminating

Utilising the latest coating techniques for the most sensitive and demanding substrates.

+ Vacuum

We’re leading suppliers of vacuum deposition systems for producing batteries and solar cells, which convert light into electricity, via the photovoltaic effect. As with our coating products, we also offer first-class vacuum development solutions through our in-house Technology Centre and team of expert, highly qualified scientists.

Our Horizons range of vacuum deposition solutions for battery and solar cell production includes the Genesis, Genesis ALD and Genesis L machines.

+ Forming

We’re leading suppliers of forming machinery that helps to manufacture automatic heat exchangers for electric vehicles. This process involves progressively forming and fluxing large rolls of aluminium and titanium. Once installed, these very complex parts permit the flows of coolant and air needed to reduce engine or battery temperatures.

Our Horizons range of forming solutions for automatic heat exchanger production includes the Tube Mill, Fin Mill and Core Assembly/Core Builder machines.

+ Tube Mill

Runs at 150 metres and 300 cuts per minute. Quick changeover – change from one model to another easily within 30 minutes.

+ Fin Mill

Capable of single or twin lane operation and up to 75 cuts and 250 per minute. Built to exacting standards with both single and twin track production.

+ Core Assembly / Core Builder

Manual output machine and fully automated solutions available.

+ Low carbon manufacturing technology built to your specification

E+R demonstrates an in-depth understanding of our customers’ low carbon machinery needs for making ecologically friendly products in an ever-changing market.

Our experienced and dedicated team includes designers, engineers, creative problem-solvers and critical thinkers who are committed to creating the best possible solution for your project or challenge.

Creating new technology and applying this to the machinery we produce is our key focus.

+ Custom development for all low carbon product applications

Our objective is to provide you with the ultimate solution that completely matches your needs, so our engineers will work with you from the concept stage to ensure you have the best possible design.

We are able to design and manufacture a range of low-carbon products to suit your machinery needs, irrespective of the origin or type. The choice is yours.

+ After sales and support

We are committed to providing the highest levels of customer service throughout your journey of working with E+R.

Our After Sales team will support you with any additional requirements and are on hand to offer advice at any stage of your eco-friendly product or project’s development.

E+R offer a range of planned maintenance contracts for forming, coating and vacuum machinery, and appraisal services for customers looking to review machine condition or plan refurbishment or upgrades.

Advanced low carbon coating, vacuum and forming machinery for the manufacturing of the future

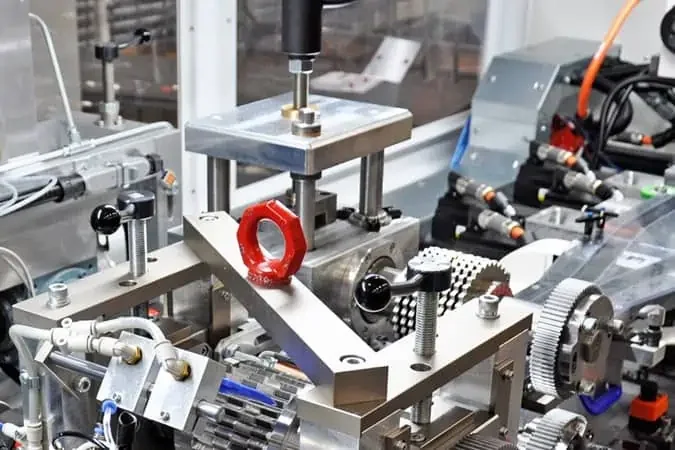

+ Engineering Capabilities

Experienced mechanical and electrical assembly and installation engineers

- Wide experience across diverse range of applications

- Mechanical assembly, set-up and calibration of machine sections in-house

- In-house panel build for control cubicles

- Installations completed globally, turn-key start-ups possible

Machine shop for the manufacture of key components

- Equipment portfolio focussed on key elements of machinery – machine frames and ties, rollers, precision components

- Early/late shift pattern

- Complete ‘ownership’ of critical components

Tool room for manufacture of precision components

- Precision equipment – wire EDM, CNC grinding and finishing

- Precision inspection and component validation equipment – CMM, Jodon etc.

Certified to ISO 9001: 2015 quality system

- Component inspection and quality validation

- Assembly validation and sign-off at FAT and SAT

- View our Quality Policy Click here

+ Manufacturing Capabilities

Experienced mechanical and electrical/control engineering team

- 18 full-time engineers

- Web transport, roller design, web guiding, spreading etc.

- Drying technologies

- Coating technologies

- Machinery sub-systems – pneumatics, hydraulics, cooling systems, vacuum

Mechanical design in 3D drafting system with sophisticated FEA

- Complex stress analysis of vacuum vessels ensures optimal design

- Stress deflection analysis for optimal precision and accuracy

Full control systems design – hardware and software

- Electrical control cubicles, HMI and operator pendants

- Wide variety of vendors – Rockwell, Siemens, Bosch Rexroth, Mitsubishi etc.

- Fully compliant safety systems

- Software design and implementation

- Complex drive algorithms – registration, dynamic positioning, tension sensitivity and processing

- Testing and commissioning of systems by E+R staff

+ Case Studies

Discover more examples of production machinery and engineering projects brought to life through E+R's unique combination of design expertise, advanced engineering skills and expert customer service. Projects where innovation, simplicity of design and inbuilt reliability come as standard.

+ New frontiers in custom built Vacuum technology

This next generation Roll to Roll PECVD vacuum coater is the result of meticulous analysis of the process and its’ behaviours...

+ Playing the long game with custom-built engineering

This month sees the conclusion of a project spanning more than two years; bringing a new machine into full production running a pre-existing process but with much improved outcomes.

+ Have you got a question for our coating, vacuum or forming teams?

Please fill in your details below and a member of our dedicated teams will be in touch. Please complete as much information as you so that we can make sure the right person picks up your enquiry.