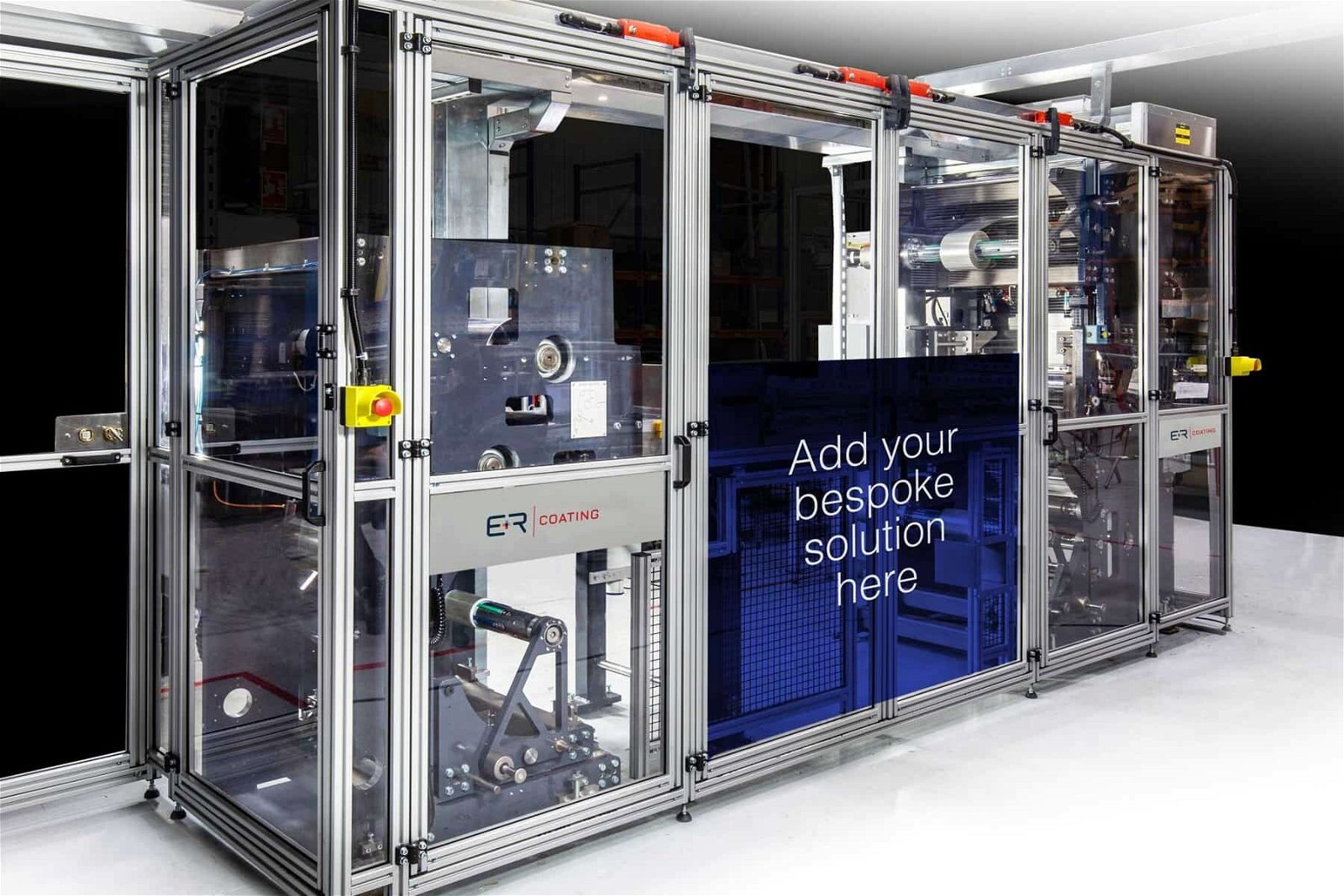

+ Retrofit and re-drives

We're Specialists in the retrofitting and redriving of existing machines - whatever the manufacturer.

Our technical team are highly experienced in the retrofitting and upgrading of existing machinery to increase performance, improve functionality, provide longevity and remove obsolescence.

Often electronics become obsolete rendering a mechanically sound print station or screenline obsolete. replacing the drive and control system can breathe new life into your production line.

E+R took a relatively new Stork SPG SP5, Screenline and replaced the entire drive and control system to improve the operational efficiency and accuracy of the unit. This saved several million pounds in capital expenditure ensuring a much longer working life for the unit.

+ Specialist in the refurbishing and retrofitting of print stations and print modules

Not only do we redrive complete production lines we also add printing modules or stand-alone stations to existing equipment integrating into your control system. In many cases, we can do this irrespective of the original manufacturer.

Our objective is to provide you with the ultimate solution that completely matches your needs, so our engineers will work with you from the concept stage to ensure you have the best possible design.

Advanced development for printing, wallpaper and wallcovering machinery

+ Engineering Capabilities

Experienced mechanical and electrical assembly and installation engineers

- Wide experience across a diverse range of applications

- Mechanical assembly, set-up and calibration of machine sections in-house

- In-house panel build for control cubicles

- Installations completed globally, turn-key start-ups possible

- Factory layout, service’s, material flow, product handling Installation, commissioning and Operator training & Material Supplier introductions.

Machine shop for the manufacture of key components

- Equipment portfolio focussed on key elements of machinery – machine frames and ties, rollers, precision components

- Early/late shift pattern

- Complete ‘ownership’ of critical components

Toolroom for manufacture of precision components

- Precision equipment – wire EDM, CNC grinding and finishing

- Precision inspection and component validation equipment – CMM, Jodon etc.

Certified to ISO 9001: 2015 quality system

- Component inspection and quality validation

- Assembly validation and sign-off at FAT and SAT

- View our Quality Policy Click here

+ Manufacturing Capabilities

Experienced mechanical and electrical/control engineering team

- 18 full-time engineers

- Web transport, roller design, web guiding, spreading etc.

- Drying technologies

- Coating technologies

- Machinery sub-systems – pneumatics, hydraulics, cooling systems, vacuum

Mechanical design in 3D drafting system with sophisticated FEA

- Complex stress analysis of vacuum vessels ensures optimal design

- Stress deflection analysis for optimal precision and accuracy

Full control systems design – hardware and software

- Electrical control cubicles, HMI and operator pendants

- Wide variety of vendors – Rockwell, Siemens, Bosch Rexroth, Mitsubishi etc.

- Fully compliant safety systems

- Software design and implementation

- Complex drive algorithms – registration, dynamic positioning, tension sensitivity and processing

- Testing and commissioning of systems by E+R staff

+ Advanced coating, printing and embossing machines for the printing, wallpaper and wallcovering market

+ Commercial Wallcovering Lines

High-speed printing, laminating and embossing machinery with special features for commercial needs.

+ Coating Machines

The full range of coating machines ideal for wallpaper and wallcovering production.

+ Gravure Printer

Special features make colour change quicker and improve press utilisation.

+ Flexo Printing

Custom manufacturing of flexo printing equipment from the development of full flexo printing lines to the creation of integrated flexo printing modules onto your existing workflow.

+ Embossing Machinery

World-renowned embossers used by leading European wallpaper manufacturers.

+ Piece Winders

Whether its rewinding a web into a large diameter reel for further processing or winding finished rolls of wallpaper ready for wrapping we have range of options for you at various widths.

+ Retrofit and re-drives

We're Specialists in the retrofitting and redriving of existing machines - whatever the manufacturer

+ Have you got a question for our Print, wallcovering and coatings Team?

Please fill in your details below and a member of our dedicated team will be in touch. Please complete as much information as you so that we can make sure the right person picks up your enquiry.

+ Print Technical Articles

Our team has a wealth of knowledge and expertise built up over decades of experience in their fields of specialism. Read our technical articles to find out how we have used this expertise, with creative problem solving and critical thinking, to meet and surpass our customers’ needs.

What Is Vacuum Coating?

From protecting tools to enabling the performance of electronics, surface coatings are a crucial part of modern engineering...

Second funding grant recognises E+R’s place at forefront of Green Battery Technology Development

E+R’s status as a pioneer in the development of ground-breaking green battery technologies has received its latest recognition through a second funding grant from the UK’s Faraday Battery Challenge.

East Lancashire engineering apprenticeship scheme seeks youngsters wanting funded training and fast career progress

We are proud to be part of a new UK-based consortium of 7 organisations (leaders at each stage in the value chain)...

Encouraging the next generation

As a leading UK engineering company, we work hard to support education and training for the next generation of Engineers.

+ Beneq and E+R Group enter strategic partnership for roll-to-roll ALD

Beneq, a leading ALD equipment manufacturer, today announces a strategic partnership with E+R...

+ Soapbox Challenge 2021

The incredibly popular Soapbox Challenge, of which E+R is a sponsor, will return for the delight of the onlookers...

+ Slot die/Offset knife over roll Battery coater

Single and double double-sided coater for Flexible LiS battery coating Pre trialing completed on E&R pilot facilities...

+ Pilot roll-to-roll bespoke application for Conductive Films

E+R delivered a pilot roll-to-roll machine, implementing the patented CondAlign technology...

+ New frontiers in custom built Vacuum technology

This next generation Roll to Roll PECVD vacuum coater is the result of meticulous analysis of the process and its’ behaviours...