PVD Vacuum Deposition Coating Machines

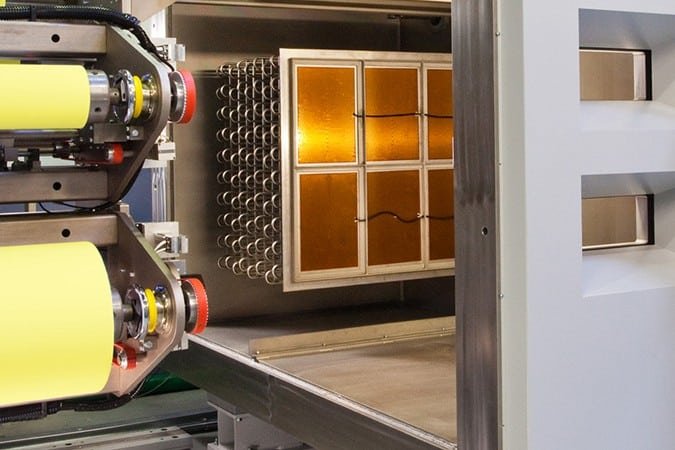

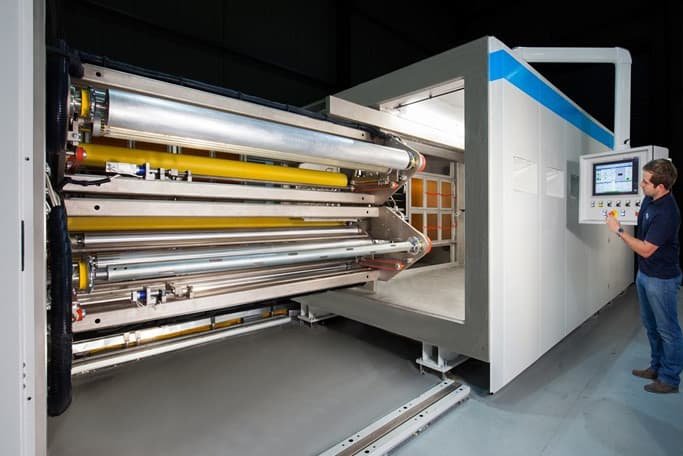

Roll-to-Roll Vacuum Coating Platforms.

Combining our engineering knowledge from machinery build and substrate handling, we offer vacuum machinery coating platforms expertly designed to the application – meeting and surpassing our customers’ needs.

These platforms include pilot scale vacuum coaters for R&D purposes or small-scale production, through to matched production machinery for customers looking to expand the width and productivity of an application with market potential.

Vacuum deposition is a successful and long-established method of coating thin films onto both flexible and rigid substrates where the application and material choice determines that atmospheric techniques would not be viable.

This equipment offers higher productivity rates, lower costs, plus differentiating specifications and applications – benefits which are gained through the vast range of methods and materials that can be utilised and subsequently coated within a vacuum chamber.

Coatings can range from being simple monolayer metals for flexible packaging applications, solar absorber layers or optical media devices, through to complex solar cell, barrier or display structures utilising multilayer approaches and varied deposition source types.

The variety of applications also have their own needs on coating porosity, uniformity and encapsulation requirements which can be addressed by using different deposition methods and or additional treatments.

These need very little or no influence from the surroundings and must be controlled using a vacuum chamber to prevent contaminants from inclusion in the final product.

+ Experience

E+R is a world-leading equipment engineering company. We have grown and developed across a number of market sectors including Print, Forming, Vacuum and Coating and we are proud to be a leading manufacturer of sophisticated roll-to-roll production machinery.

+ Expertise

E+R puts innovation, creativity and invention at the heart of everything we do. We continue to invest in research projects to explore the limits of engineered solutions for our customers and we are committed to challenging the status quo.

We work collaboratively with partners in private industry and from the world of academia to ensure we remain at the cutting edge of innovation.

+ Advanced Vacuum Solutions

+ Commercial Vacuum coating equipment built to your specification | Industrial Vacuum Machine For Sale

E+R demonstrates an in-depth understanding of our clients’ vacuum needs in an ever-changing market.

Our experienced and dedicated team include designers, engineers, creative problem-solvers and critical thinkers who are committed to creating the best possible solution for your project or challenge.

Creating new technology and applying this to the machinery we produce is our key focus.

+ Informed thinking for all your Vacuum coating machine development needs

Technique, technology and innovation.

E+R equipment utilises many deposition techniques including (but not limited to) :-

Sputtering – (Rotatable & Planar Cathodes), ALD – (Atomic Layer Deposition), RIE – (Reactive ION Etch), E-Beam (Electron Beam), PECVD – (Plasma Enhanced Chemical Vapour Deposition), Plasma Treatment.

State-of-the-art production equipment.

Custom-designed machines to suit a range of applications:-

Display, Battery, Energy Storage, Window Film, Solar, Anti Reflective, Anti Static, Mouldable plastics, Flexible Electronics, Barrier, Security, Decorative coatings.

+ After Sales

We are committed to providing the highest levels of customer service throughout your journey of working with E+R.

Our After Sales team will support you with any additional requirements and are on hand to offer advice at any stage of your product or project’s development.

E+R offer a range of planned maintenance contracts for Vacuum and appraisal services for those looking to review machine condition or plan refurbishment or upgrades.

Advanced Vacuum coating development expertise.

+ Engineering Capabilities

Experienced mechanical and electrical assembly and installation engineers

- Wide experience across diverse range of applications

- Mechanical assembly, set-up and calibration of machine sections in-house

- In-house panel build for control cubicles

- Installations completed globally, turn-key start-ups possible

Machine shop for the manufacture of key components

- Equipment portfolio focussed on key elements of machinery – machine frames and ties, rollers, precision components

- Early/late shift pattern

- Complete ‘ownership’ of critical components

Tool room for manufacture of precision components

- Precision equipment – wire EDM, CNC grinding and finishing

- Precision inspection and component validation equipment – CMM, Jodon etc.

Certified to ISO 9001: 2015 quality system

- Component inspection and quality validation

- Assembly validation and sign-off at FAT and SAT

- View our Quality Policy Click here

+ Manufacturing Capabilities

Experienced mechanical and electrical/control engineering team

- 18 full-time engineers

- Web transport, roller design, web guiding, spreading etc.

- Drying technologies

- Coating technologies

- Machinery sub-systems – pneumatics, hydraulics, cooling systems, vacuum

Mechanical design in 3D drafting system with sophisticated FEA

- Complex stress analysis of vacuum vessels ensures optimal design

- Stress deflection analysis for optimal precision and accuracy

Full control systems design – hardware and software

- Electrical control cubicles, HMI and operator pendants

- Wide variety of vendors – Rockwell, Siemens, Bosch Rexroth, Mitsubishi etc.

- Fully compliant safety systems

- Software design and implementation

- Complex drive algorithms – registration, dynamic positioning, tension sensitivity and processing

- Testing and commissioning of systems by E+R staff

+ Case Studies

Discover more examples of production machinery and engineering projects brought to life through E+R's unique combination of design expertise, advanced engineering skills and expert customer service. Projects where innovation, simplicity of design and inbuilt reliability come as standard.

+ New frontiers in custom built Vacuum technology

This next generation Roll to Roll PECVD vacuum coater is the result of meticulous analysis of the process and its’ behaviours...

+ Playing the long game with custom-built engineering

This month sees the conclusion of a project spanning more than two years; bringing a new machine into full production running a pre-existing process but with much improved outcomes.

+ Have you got a question for our Vacuum Team?

Please fill in your details below and a member of our dedicated team will be in touch. Please complete as much information as you so that we can make sure the right person picks up your enquiry.